Aluminum alloy cable

Category:

Aluminum alloy cable

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Aluminum alloy cable

PRODUCT DETAILS

Aluminum alloy cable is a power transmission cable using aluminum alloy as the main conductor. Its material is lightweight and has good conductive performance, which is suitable for transporting large -current power systems. Aluminum alloy cables are widely used in construction, industry, transportation and other fields, and can be used for transmission lines and power transformer connections.

The function of aluminum alloy cables is to transmit power signals to ensure the normal operation of the power system. Its long service life, abrasion resistance, antioxidant, high temperature resistance and other characteristics make it an important choice in power transmission cables.

The advantage of aluminum alloy cable is the characteristics of its material lightweight, excellent conductivity, long service life, and convenient installation and maintenance, which can provide users with stable and reliable power transmission services. In addition, the price of aluminum alloy cables is relatively low, which is a cost -effective power transmission cable product.

When using aluminum alloy cables, you need to pay attention to avoid external force damage, keep dry and clean, and prevent long -term overloading to ensure its normal operation and extend the service life. Choosing the appropriate specifications of aluminum alloy cables and installation in accordance with the correct installation method can better play its effect and ensure the stable operation of the power system.

Product execution standard

This product is designed and manufactured according to the GB/T 31840.1-2015 "Rating voltage 1kV to 35kV aluminum alloy core extrusion insulating power cable part 1: rated voltage 1kV to 3kV cable".

Product characteristics and use

This product is suitable for electrical energy transmission in the 1KV and 3KV transmission and distribution systems. It has the characteristics of light weight and moisture -proof, which can be laid directly in indoor and outdoor burial, bridge, pipelines, brackets, cable signs, etc.

Work temperature and layout conditions

1) The rated voltage of the construction frequency U0/U 0.6/1kV.

2) The long -term allowable maximum temperature of the cable conductor does not exceed 90 ° C.

3) The maximum temperature of the cable conductor does not exceed 250 ° C during short -circuit (the longest does not exceed 5s).

*Lie on the ground

4) The ambient temperature of the cable should not be less than 0 ° C.

5) The curved radius of the cable is:

Single core cable: 20D

Three -core cable: 15D

Product characteristics

(1) Electrical performance

The conductivity of the Mingda aluminum conductor is between aluminum and copper. Under the same load capacity, the weight of the same length of the aluminum alloy conductor is only half of the copper conductor. When the cross -sectional area of the aluminum alloy conductor is 1.5 times that of copper, its electrical performance is the same, that is, the same load capacity, resistance, and voltage loss of the same as the copper.

(2) Anti -creep degeneration

The Mingda aluminum alloy conductor adds a variety of metal elements such as iron, copper, zinc, magnesium, and rare earth, and uses a unique thermal treatment process, which greatly reduces the "creep" tendency of metal under thermal and pressure. The connection performance is greatly improved, especially when the conductor anneal, the added alloy element produces high resistance degeneration, and even overload and overheating can ensure the stability of the connection.

(3) Connection performance

The connection performance of Mingda aluminum alloy cables and gold gear has been passed through the GB/T9327 1000 thermal cycle test, which proves that the long -term stability and reliability of Mingda aluminum alloy cable connection is the only basis for judging the quality of connection.

(4) Corrosion resistance

Aluminum quickly forms a dense oxide film with a thickness of about 2x10-4mm in the air to prevent further corrosion of internal metals. As the aluminum alloy conductor of Mingda added rare earth elements such as Cerium and Lanthanum, the corrosion resistance of metal materials with aluminum -based conductors was further improved. The corrosion resistance of aluminum alloy is much better than copper in a sulfur environment.

(5) Mechanical performance

High extension rate: The elongation rate of Mingda Aluminum Conduct can reach more than 30%, which is an important indicator for measuring the quality of the product and the ability to withstand external forces.

Strength and toughness: The flexibility of Mingda Aluminum alloy is 25%higher than copper. Even repeatedly will not crack, reducing hidden safety hazards during the installation process.

Easy bending: The minimum curved radius of Mingda Aluminum alloy cable is 7 times that of the outer diameter of the cable, which reduces the installation and layout space. It is easier to laying and save installation costs.

Low rebound: The rebound angle of Mingda aluminum alloy cable is 40%smaller than the copper cable, which is more conducive to the tightness of the terminal connection connector, easy to compress, and improve the stability of the connection.

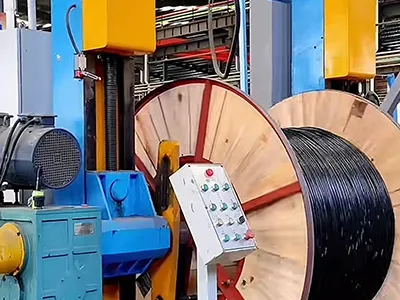

FACTORY

HONOR

Customer communication

COMMON PROBLEM

APPLICATION SCENARIOS

Power field

Communicate

Architecture

Ship manufacturing

Transportation

Architecture

GET A FREE QUOTE

RELATED PRODUCTS